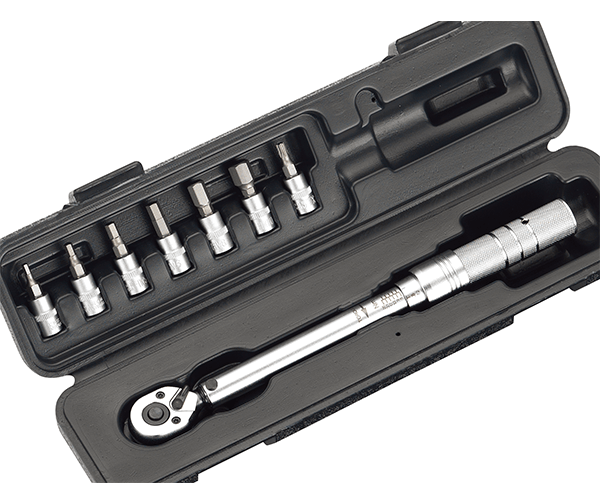

Comprehensive Overview of Torque Wrench Manufacturing Steps #

Premium quality in torque tools is achieved through meticulous process control and continuous refinement. At Torque-Tech, our expertise is reflected in a series of proprietary patents and ongoing improvements to our manual hand torque wrench products, ensuring they meet the highest standards of performance and reliability.

Commitment to Process Control and Quality #

Manufacturing management is central to delivering quality products. Our approach encompasses not only process control and assembly services, but also robust quality assurance and supply chain management. Consistency in production is maintained through continuous process operations, which are essential for producing reliable and high-performing torque tools.

Key Manufacturing Stages #

The production of our torque wrenches involves a comprehensive sequence of operations, each contributing to the final product’s durability, safety, and ergonomic design. The main stages include:

- Tube extrusion

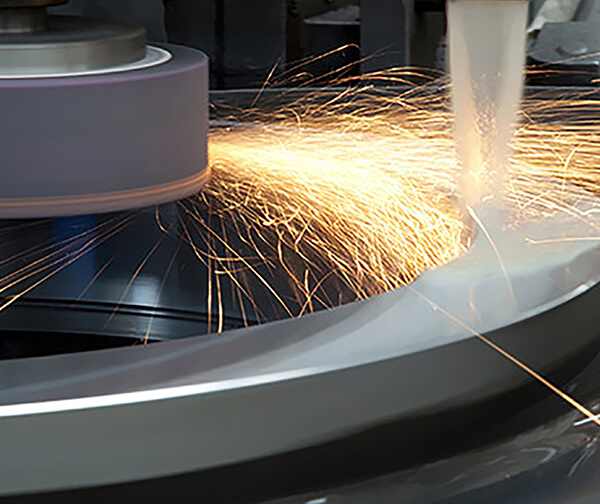

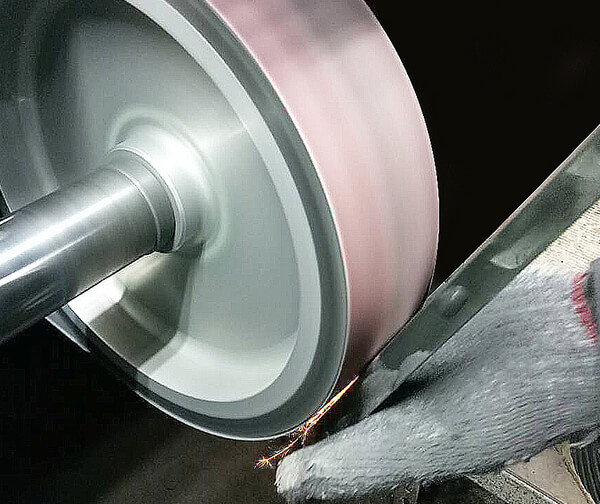

- Grinding (surface and centerless)

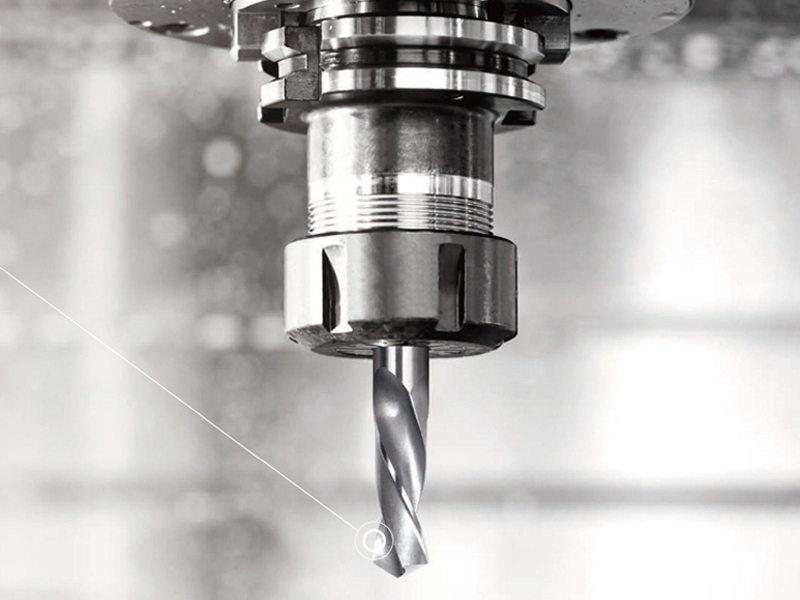

- Milling (CNC)

- Lathing (CNC)

- Drilling

- Grooving

- Heat treatment

- Polishing

- Sand blasting

- Electro-plating

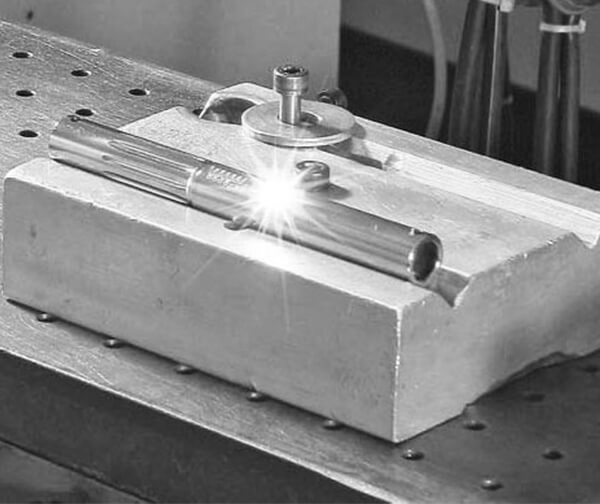

- Laser marking

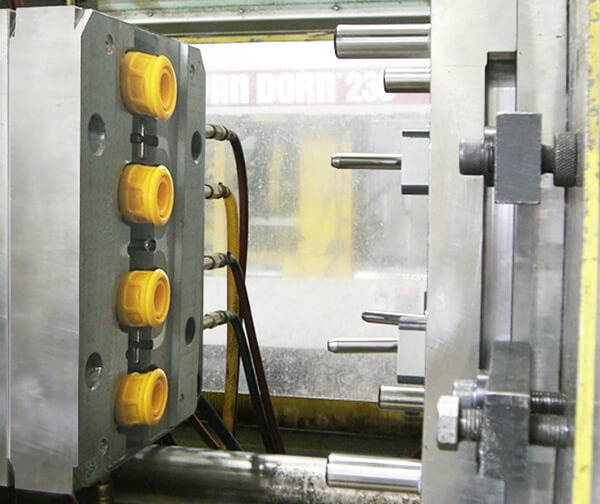

- Assembly

- Calibration

- Packaging

- Final quality inspection

We believe that premium quality is achieved by optimizing material properties, ensuring ergonomic perfection, and maximizing both safety and product lifespan. Our torque tools are designed to meet the diverse needs of various industries. When standard solutions are not sufficient, we also offer customized tool development to address specific technical challenges.

Step-by-Step Manufacturing Process #

Each of these steps is carefully monitored and executed to ensure the final product meets our stringent quality standards. Our dedication to process control and innovation allows us to deliver torque tools that are both reliable and tailored to the needs of our customers.