Precision Standards in Torque Tool Calibration #

Torque-Tech Precision Co., Ltd. established an in-house calibration laboratory in 2013, dedicated to ensuring the accuracy and reliability of manual torque tools, mechanical test devices, and torque transducers. The laboratory is internationally accredited and operates under rigorous quality standards, providing confidence in every product delivered.

Laboratory Accreditation and Compliance #

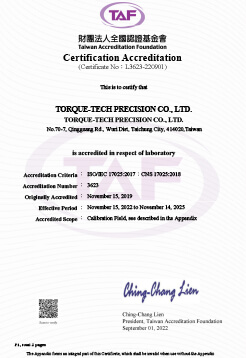

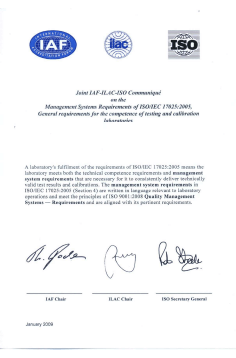

- The laboratory received accreditation from the Taiwan Accreditation Foundation (TAF) in 2012 and is a member of the ILAC MRA signatories, reflecting its commitment to global standards.

- Calibration procedures adhere to ISO/IEC 17025:2017, ensuring technical competence and consistent results.

- All torque wrenches are calibrated in accordance with DIN ISO 6789 and ASME B107.300-2010 standards.

- The internal quality management system aligns with ISO 9001:2015 requirements.

Calibration Capabilities and Technical Highlights #

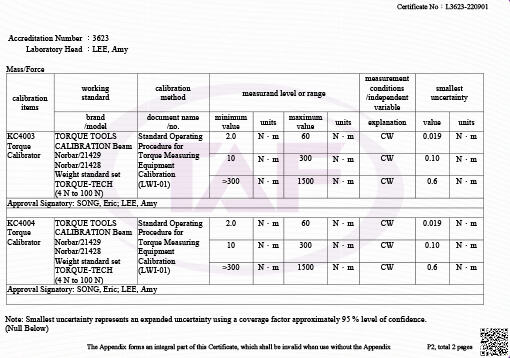

- The laboratory is equipped to calibrate torque tools up to 1500 N·m.

- Calibration is performed using computer-controlled testers, guaranteeing 100% testing of all products.

- Applied torque measurements achieve an uncertainty of less than 0.02%.

- The machining precision of the calibration beam is maintained within ±0.01%.

- The laboratory’s gravity value is set at GA = 978824.50 (MGAl), supporting precise calibration results.

Accreditation Certificates #

ISO/IEC 17025:2017 Certificate

ISO/IEC 17025:2017 Certificate

ISO/IEC 17025:2017 Certificate (Page 2)

ISO/IEC 17025:2017 Certificate (Page 2)

ISO/IEC 17025:2005 Certificate

ISO/IEC 17025:2005 Certificate

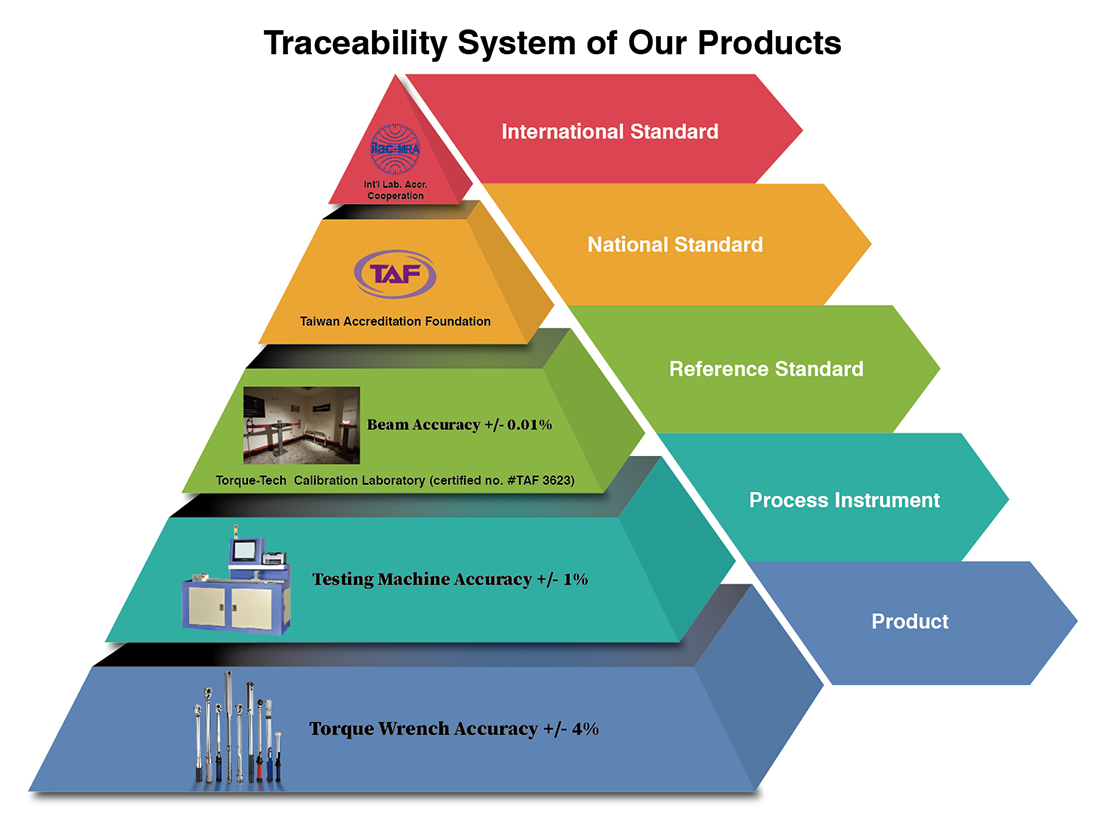

Product Traceability System #

To further enhance quality assurance, a comprehensive traceability system is implemented for all products. This system ensures that every torque tool can be tracked throughout its lifecycle, supporting accountability and transparency in calibration and manufacturing processes.